Blog

future trends in the manufacturing industry how to prepare for market changes

The manufacturing industry is in the midst of a profound transformation, driven by a combination of rapid technological advances, changing consumer preferences, and a growing emphasis on sustainability. To thrive in this dynamic environment, businesses must not only be aware of emerging trends but also take proactive steps to adapt. This article will review some of the key trends shaping the future of manufacturing, focusing on how companies like Manu Group can prepare for these changes and maintain a competitive edge.

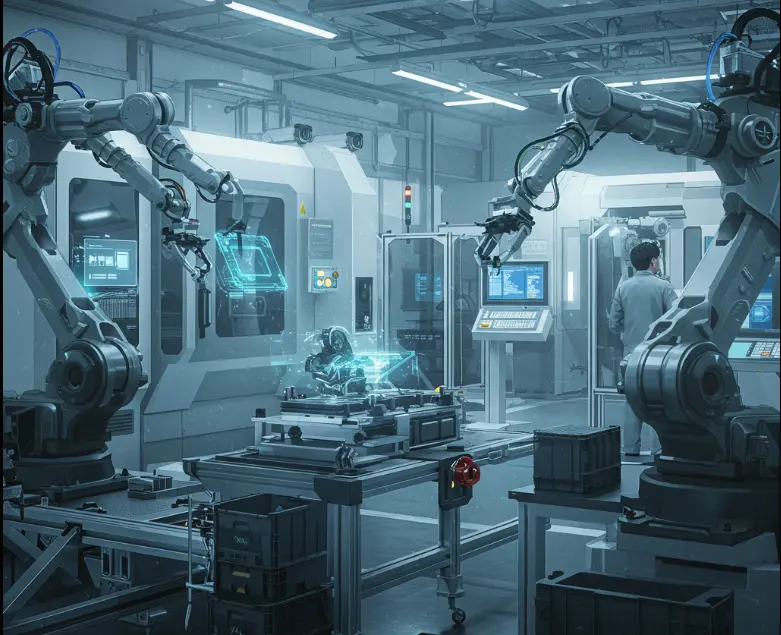

Advanced automation and artificial intelligence

One of the key trends driving change in the manufacturing industry is the accelerated adoption of advanced automation and artificial intelligence (AI). Increasingly capable robots, computer vision systems, and machine learning are changing the face of the modern factory.

- effect: Automation allows manufacturers to achieve higher levels of efficiency and accuracy, reduce labor costs, and improve product quality. Robots can perform dangerous or monotonous tasks, thereby improving worker safety and working conditions. AI can streamline manufacturing processes, predict equipment failures, and improve production planning.

- The preparation: For companies like At Mano Group, preparation includes a thorough review of existing production processes and identifying areas where automation solutions can be integrated. Investing in AI technologies and developing relevant skills among employees is essential to fully realize the potential of these technologies.

Moving to customized and distributed manufacturing

Consumers today expect products tailored to their specific needs and fast delivery times. This trend is pushing the manufacturing industry towards more flexible and distributed models.

- Impact: Technologies like 3D printing (additive manufacturing) allow products to be manufactured on demand and at different points, closer to customers. This shortens the supply chain, reduces shipping costs, and allows for greater flexibility in designing and manufacturing customized products.

- Preparation: Mano Group can explore the possibility of integrating additive manufacturing technologies to offer customized products and improve the speed of response to changes in market demand. Developing a distributed production network, using digital platforms for order management and production, can provide a significant advantage.

Sustainability and circular economy

Growing environmental awareness and the demand for sustainable solutions are having a profound impact on the manufacturing industry. There is an increasing emphasis on waste reduction, resource efficiency, and a transition to a circular economy.

- Impact: Tighter environmental regulations and pressure from consumers and stakeholders are leading companies to implement greener manufacturing practices. This includes using recycled and sustainable materials, reducing energy and water consumption, and designing products to be easy to recycle at the end of their life cycle.

- Preparation: Mano Group can focus on integrating sustainability principles into all stages of production, from material selection to manufacturing processes and product distribution. Being transparent about these efforts and communicating with customers about the environmental benefits can strengthen the brand and attract environmentally conscious customers.

Data Connectivity and Industrial Internet of Things (IIoT)

The connection of machines, sensors, and manufacturing systems via the Industrial Internet of Things (IIoT) creates a massive stream of real-time data. Utilizing this data through advanced analytics can lead to significant improvements in efficiency and performance.

- Impact: IIoT enables remote monitoring of equipment, predictive maintenance that reduces downtime, optimization of production processes in real time, and improvement of product quality through early identification of problems.

- Preparation: Mano Group can invest in developing an IIoT infrastructure to collect and analyze data from its manufacturing operations. This requires a combination of sensors, communication systems, and advanced software systems, as well as developing data analytics skills within the organization.

Human-machine collaboration (Cobots)

The future of manufacturing is not necessarily just about full automation, but also about a smart combination of human workers and collaborative robots (cobots). Cobots are designed to work safely alongside humans, and assist with various tasks.

- Impact: Cobots can improve efficiency and safety by performing physical or repetitive tasks, while human workers can focus on tasks that require cognitive, creative, and problem-solving skills. This collaboration can lead to higher productivity and a more ergonomic work environment.

- Preparation: Mano Group could explore the possibility of integrating cobots into its production lines to improve work processes and free employees from tedious tasks. Implementing cobots requires careful planning and training employees to work with robots.

By focusing on these trends and adopting new technologies and approaches, companies like Mano Group can build a prosperous future for themselves in the ever-evolving manufacturing industry. Adapting to change, investing in innovation, and developing human capital are the keys to success in the advanced manufacturing era.